DTS | Direct Controlled

External Continuous

Damping Valves (NO)

Customizable damping, proven reliability, and seamless integration for enhanced suspension performance

Precise damping control with DTS Valves for Active Suspension Systems

With DTS – Direct Controlled External Continuous Damping Valve (NO) Solero Technologies offers a high-performance valve designed for precise control over damping forces in active suspension systems. With an identical hydraulic and mechanical interface to the series design, this valve ensures seamless integration and delivers comparable functionality to standard products.

Engineered with Solero’s proprietary intellectual property and a cost-optimized design, the DTS valve combines high reliability, robust performance, and flexibility. It offers five variable defined cracking points, a wide temperature range, and compatibility with customer-specific PWM for dynamic damping control.

With more than 10 million units produced, the DTS valve demonstrates Solero’s extensive experience in delivering high-quality, efficient damping solutions that improve suspension performance, comfort, and vehicle handling.

Working principle

Dynamic control

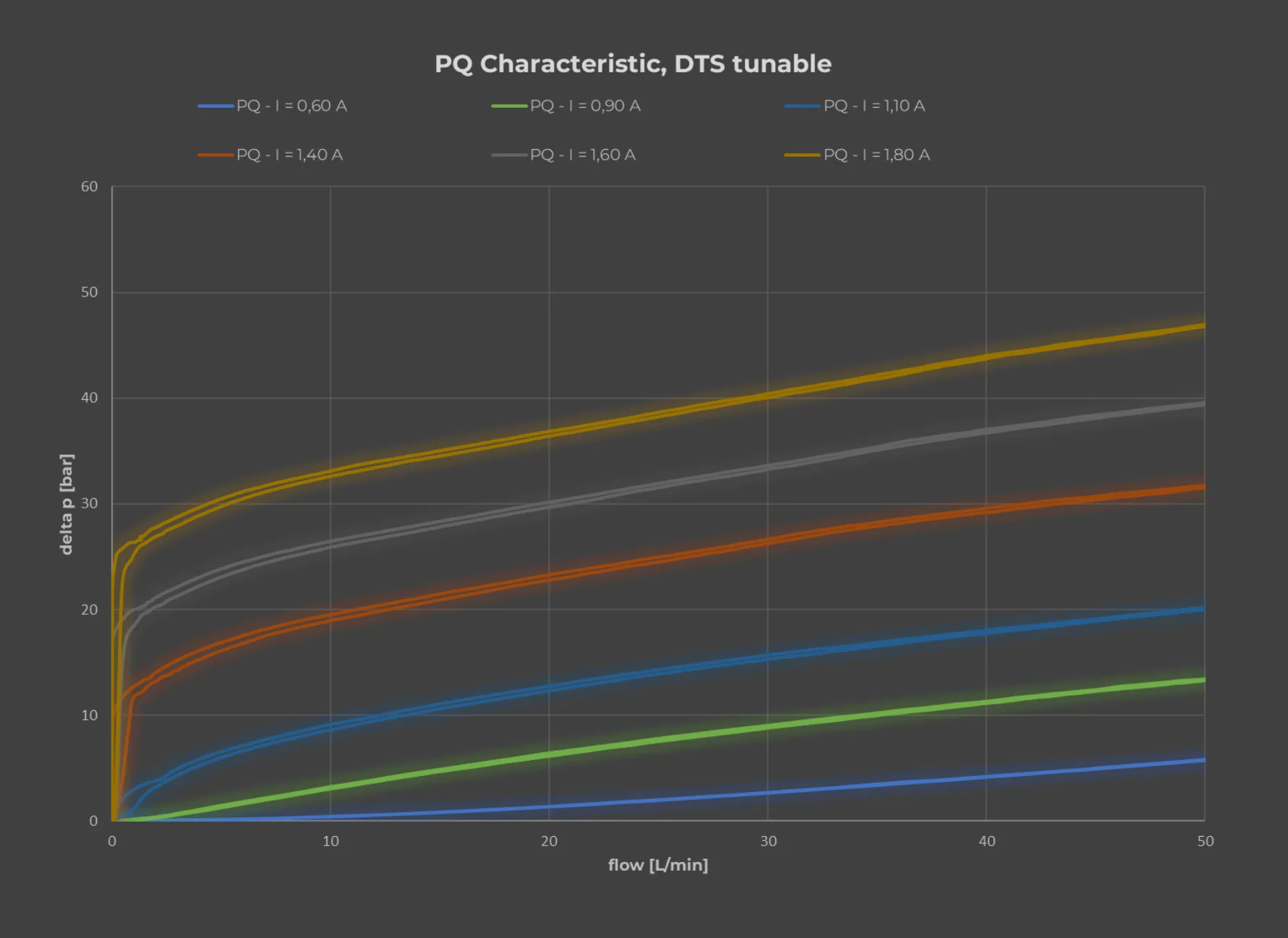

The DTS Valve works by controlling the flow of hydraulic fluid through a damping system to adjust damping forces based on real-time input signals. It utilizes pulse-width modulation (PWM) to adjust the damping characteristics continuously, allowing for precise control over the suspension’s performance.

At its core, the valve responds to PWM signals (customer-specific), altering the flow rate and pressure within the system. The five variable defined cracking points ensure that the valve can precisely adjust damping force based on specific driving conditions, offering dynamic responses to varying road surfaces and vehicle loads.

Designed to operate in extreme conditions, the valve functions within a temperature range from -40°C to 120°C and can withstand pressures up to 250 bar. The Solero IP enables the valve to deliver reliable performance while remaining cost-efficient. With a low power consumption and optimized design, the DTS valve provides an ideal solution for active suspension systems that demand precise, continuous damping control.

Benefits at a glance

- Precise Damping Control

Continuous, real-time adjustment for optimized suspension performance - Customizable Performance

Five variable cracking points and customer-specific PWM for tailored solutions - Wide Temperature Range

Operates effectively from -40°C to 120°C, ensuring reliability in extreme conditions - Cost-Optimized Design

High performance at a cost-effective price, ideal for active suspension systems - Proven Reliability

Over 10 million units produced, backed by Solero’s patented technology and years of expertise

Technical specifications

DTS – Direct Controlled External Continuous Damping Valve (NO)

Technical data

Valve type:

Non-piloted

2/2 proportional valve

Operating current:

Iop = 0 …1,8 A

(PWM = 200 Hz for validation and EOL)

PWM = customer specific

Coil restistance:

R20 = 2,9 ± 0,14 Ω

Environmental temperature:

Tenv = -40 °C to 120 °C

Max. operating pressure:

pmax = 250 bar

Allowed coil temperature:

Tcoil,allowed = 180 °C

Mass:

~ 370 g

Δp @ 50 l/min (fully open):

~ 4,5 bar

Tuning:

5 variable defined cracking points available