iCDA | Internal Controlled

Damping Actuator

The iCDA combines innovative technology with customizable features for a tailored damping solution

Optimize every drive: Adaptive Chassis Technology for peak performance

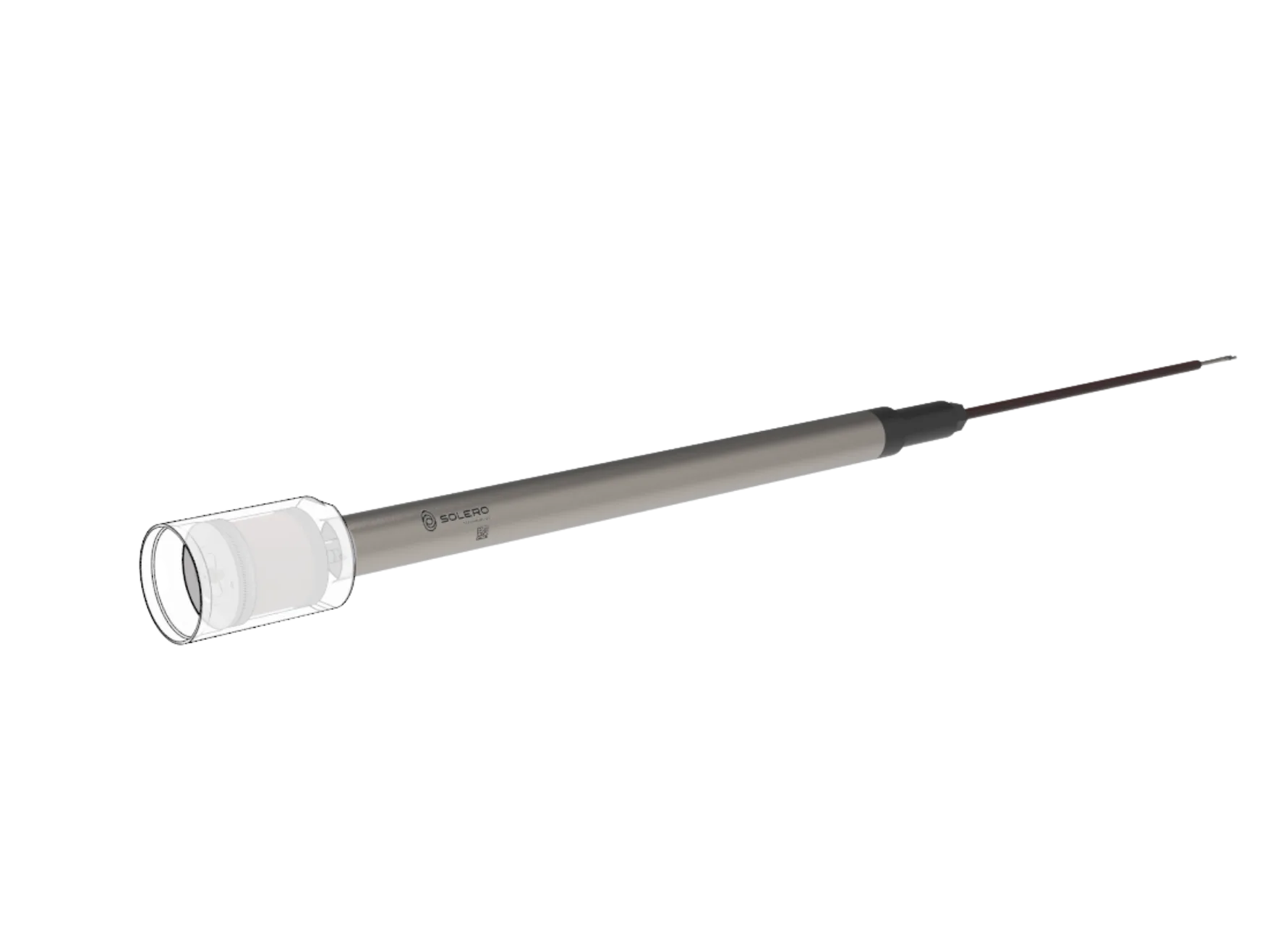

Solero’s Internal Controlled Damping Actuator (iCDA) is designed to revolutionize active suspension systems by providing precise control over damping performance. Engineered for integration into your system, the iCDA offers unmatched flexibility and efficiency in optimizing suspension characteristics.

This innovative actuator is perfect for internal damper valves, directly assembling into the customer’s piston rod, ensuring seamless integration and enhanced performance. With a patent-protected design and a range of customizable features, the iCDA provides high adaptability to fit your specific needs. Whether you require unique force-stroke characteristics or varied interface options, this actuator is up for the challenge.

With the iCDA, you gain a solution that evolves with your needs, ensuring consistent performance in advanced active suspension systems.

Working principle

Dynamic control

The Internal Controlled Damping Actuator (iCDA) operates based on a dynamic feedback loop that allows it to adjust damping characteristics in real-time, ensuring optimal suspension performance under varying driving conditions. At its core, the iCDA uses active magnet technology to control the movement of an internal piston, altering the flow of hydraulic fluid to change damping forces precisely.

When integrated into the system, the iCDA directly connects to the customer’s piston rod. This seamless integration allows the actuator to control the damper valve within the suspension system, adjusting the damping force according to the forces acting on the vehicle. The result is continuous real-time adaptation, ensuring the suspension system responds to road conditions, driving style, and external forces efficiently.

The active magnet within the actuator works in conjunction with a series of electronic control units (ECUs), which monitor and adjust the damping force dynamically. This allows the system to optimize the balance between ride comfort and vehicle stability, minimizing unwanted vibrations and ensuring superior handling. Additionally, the iCDA’s customizable features, such as force-stroke characteristics, resistance, and interface options, allow it to be finely tuned for each application. This makes it ideal for next-generation active suspension systems, where precise control and adaptability are paramount for superior driving experiences.

With the iCDA, you’re not only gaining precision in damper control, but you’re also ensuring that every drive is optimized for peak performance, comfort, and safety.

Benefits at a glance

- Patent-protected design

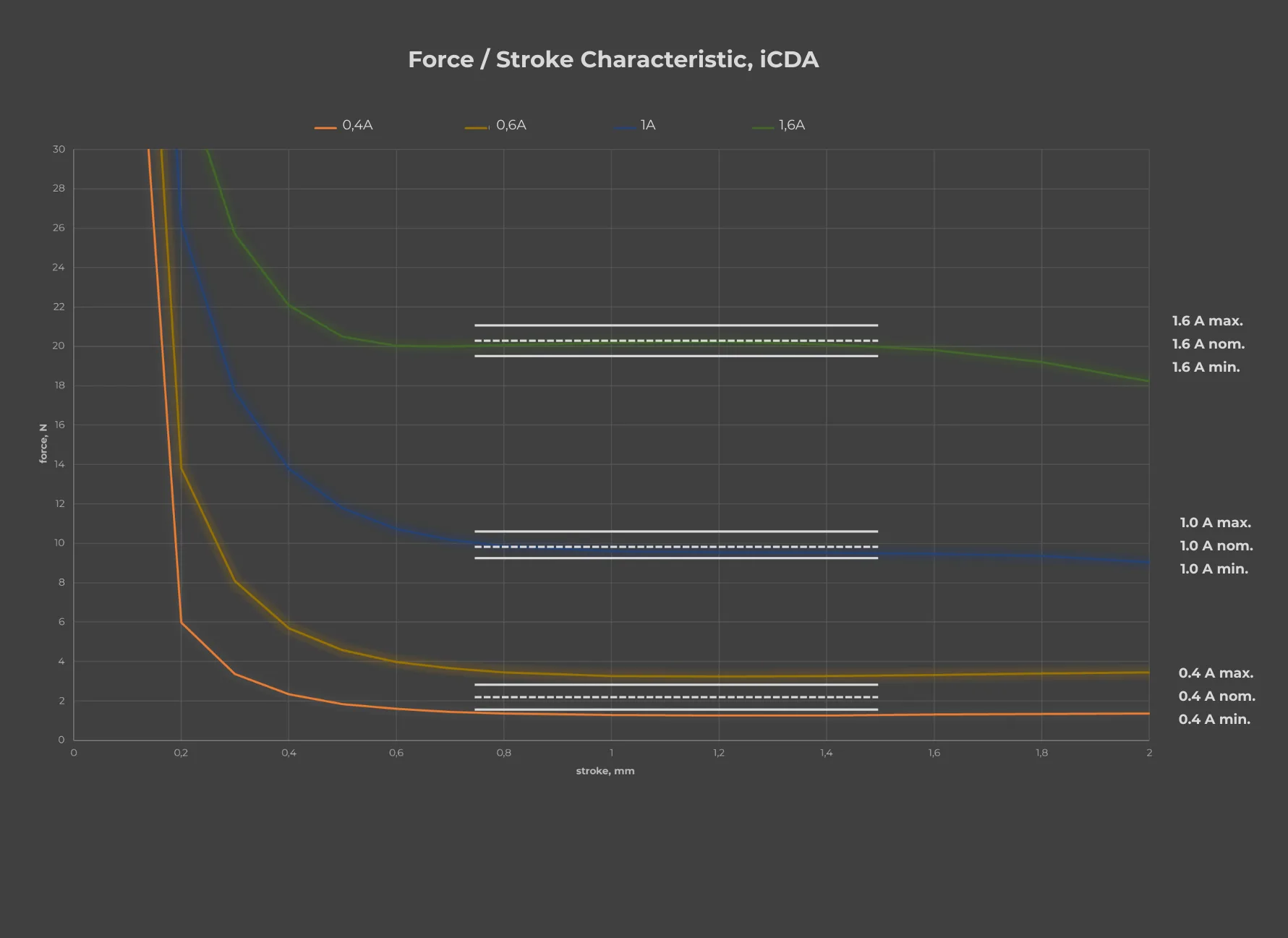

- High variability in interfaces and force-stroke characteristics

- Cost-efficient design

- Direct assembly into customer piston rod

Variable Features:

- Axis position / Stroke

- Force / Stroke Characteristic

- Resistance

- Valve interference

- Piston rod diameter and length

- Customer’s connection (cable/plug)

- Labeling position and content

Technical specifications

iCDA – Actuator for internal damper valve

Technical data

Resistance:

4.38 Ω ± 0.6%

Current:

0.4 to 1.6 A

Nominal voltage:

12 VDC

Stroke:

2 mm

Operating pressure:

150 bar

Thermal app. area:

-40°C to 140°C

Returning spring:

NO