LINNIG

A/C Compressor Clutches

Demand-oriented air conditioning in buses & special vehicles

Trust the Original – LINNIG A/C Compressor Clutches

LINNIG A/C compressor clutches are used throughout the world in bus, coach & special vehicle applications under the harshest conditions. They are designed to fit all significant compressor types on the market and are available as shaft-mounted or housing- mounted models. Our clutches meet the requirements of ISO 9001 as well as ISO 14001 and can be sampled according to the PPAP and PFF process.

Working principle

Boost air conditioning efficiency with the LINNIG electromagnetic clutch

The LINNIG electromagnetic clutches for air conditioning compressors serve as the connecting link for power transmission between the crankshaft and the compressor. The clutch engages and disengages the air conditioning system as needed, ensuring targeted use and positively impacting energy efficiency.

LINNIG clutches are used in all well-known A/C compressors. They are mounted directly onto the compressor and, in most cases, driven by belts.

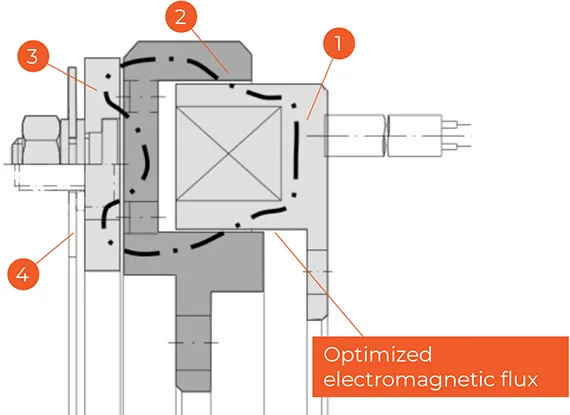

The basic structure of the LINNIG compressor clutch is as follows:

- The electromagnet (1) is fixed to the housing.

- The rotor (2) is connected to the shaft of the driven unit (“shaft-mounted,” see illustration) or mounted on the compressor (“housing-mounted”).

- The armature plate (3) with a spring (4) is connected to the drive.

- When the magnet is energized, the electromagnetic flux flows through the rotor into the armature plate, completing the circuit as illustrated.

- The armature plate is attracted to the rotor by the magnetic flux, creating a frictional connection and engaging the clutch.

Shaft-mounted

Benefits shaft-mounted clutches for a/c compressors

- Easy installation

- Slim designs possible

- Weight-optimization possible with aluminium pulleys

- Service-friendly through use of standard ball bearings

- Wide range of pulley diameters possible, owing to the ingenious design | Even small pulley diameters possible for increased weight reduction

Technical specifications

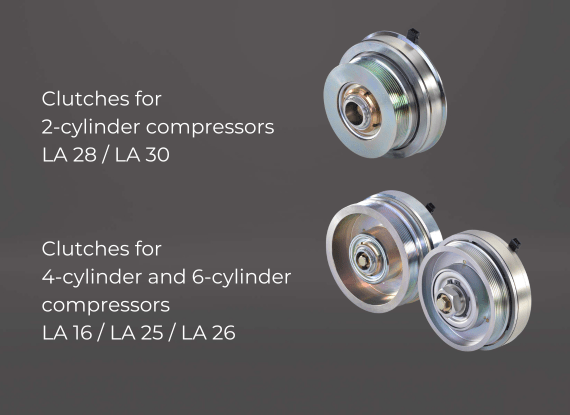

Clutches for 2-cylinder compressors LA21 / LA28 / LA30

Applications

Bock:

FKX20

FKX30

Speed

Max. permissible:

3,500

Voltage

Volt:

12 V

24 V

Clutches for 4-cylinder and 6-cylinder compressors LA16 / LA25 / LA26

Applications

Bock/Bitzer:

FKX40

FKX50/460…775

FKX50/830

FKX50/980

4UFC(Y)…4NFC(Y)

6UFC(Y)…6TFC(Y)

6PFC

6NFC

Speed

Max. permissible:

3,500

Voltage

Volt:

12 V

24 V

LA16

LINNIG A/C Compressor Clutch – Maintenance and Repair Instructions

Housing-mounted

Benefits housing-mounted clutches for a/c compressors

- Maintenance-friendly

- Slim designs possible

- No false brinelling, as the bearing rotates both when the clutch is engaged and disengaged

- Belt forces are absorbed by the compressor housing, relieving the shaft and thus the compressor bearing from belt forces.

- Durable and robust through high wear reserve

Technical Specifications

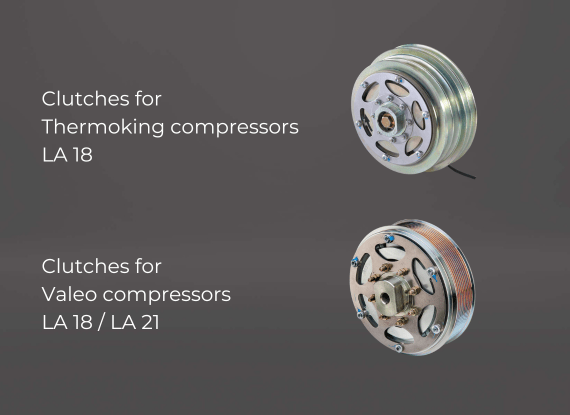

Clutches for Thermoking compressors LA18

Applications

X426/X430

S391/S616

Speed

Max. permissible:

3,500

Voltage

Volt:

12 V

24 V

Clutches for Valeo compressors LA18 / LA21

Applications

TM65

TM55

TM43

TM31

Speed

Max. permissible:

depending on compressor between 4,000 and 6,000 rpm

Voltage

Volt:

12 V

24 V