LINNIG

Belt Drive Systems

Enhancing engine efficiency with advanced belt management

Trust the Original – LINNIG Belt Drive Systems

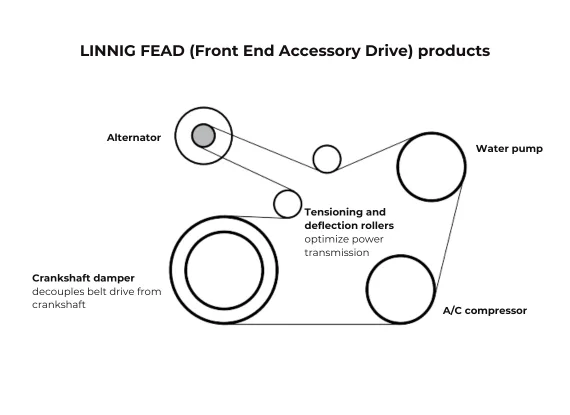

A look under the engine bonnet of your bus or coach will reveal several LINNIG components in the areas of engine cooling, air conditioning and belt management.

State-of-the-art technology provides for quiet running in the engine compartment. By deploying deflection and tension rollers, with or without damping function, as well as the torsional vibration damper, belt-management systems are tailored to customer requirements.

Trendsetting.

Intelligent.

Efficient.

Experience next-level efficiency and reliability with our high-performance belt drive systems. Engineered for modern drive technology, ISO 9001 & 14001 certified, and made in Markdorf, Germany.

99.5%

Efficiency

>95%

Vibration isolation

100%

Extended service

life of FEAD

components

300Nm

Maximum

transmissible

torque

Decouplers

Enhancing engine efficiency and reducing vibration for hybrid and diesel applications

Thanks to LINNIG’s decoupling system, buses and trucks experience a new dimension of smooth belt drive. Our technical solutions support increasing hybridization, downsizing, and reduced displacement, as well as downspeeding and efficient low-speed operation. We also enhance performance under higher compression and injection pressures.

Diesel engines run unevenly – especially in the lower speed range – causing high levels of vibration at the crankshaft. These vibrations are transmitted via the drive belts to the auxiliary units, such as the A/C compressor and the fan drive. The consequences are noise emissions, wear and fastening problems as well as increased energy consumption. This is where the LINNIG decoupler LDD comes in. It ensures smooth running in the engine compartment, while increasing the service life of the auxiliary units and improving energy balance! The LINNIG LDD eliminates 99.5% as a decoupler and only 0.5% as a crankshaft damper.

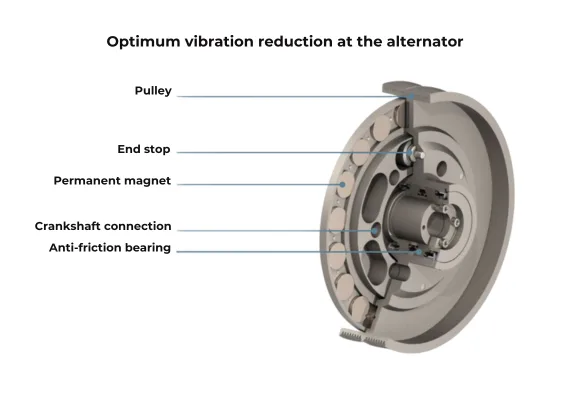

Optimum vibration reduction at the alternator

In the future, the problem will increase even more with the use of mild hybrid systems. Thanks to its flexible installation, the torsional vibration decoupler can be used for a variety of arrangements in the engine compartment.

The LINNIG decoupling system enables a double effect on the crankshaft pulley, based on the following two elements:

- Permanent magnets effect a more progressive and smooth “decoupling” function when transmitting power in the operating range of the FEAD

- Special rubber dampers serve as a buffer to enable the full force transmission of maximum torque

Benefits at a glance

- Extended Component Lifetime

Increased lifespan of belts and accessories - Improved Efficiency

Reduced fuel consumption and CO₂ emissions by lowering belt tension - Reliable Performance

Ensuring continuous belt tension with no slippage or flapping, even in extreme conditions - Easy Installation

Plug-and-play replacement with no additional modifications required - Maintenance-Free Operation

No self-heating, no losses, and no friction for long-term reliability

Technical specifications

Decouplers

Max. decoupling torque:

300 Nm

Max. diameter:

350 mm

Max. length:

120 mm

Ambient temp. limit:

-40°C short time; 120°C durable; 135°C short time

Max. temporary ambient

radial load:

5000 N

Ambient radial load:

2800 N

Tensioner pulleys with integrated decoupling system

Significant noise reduction

Significant noise reduction – The function of LINNIG’s tensioner pulleys with integrated decoupling system is to reduce noise in the mechanical drive. LINNIG’s technology plays an important role in the area of noise reduction: our idlers with integrated decoupler will keep noise well below the sound emission reference values.

With our system, you decouple the belt drive from the gear drive. This prevents the gear wheel teeth from rattling. This is very important, especially at idling speed. This product is mainly used in mechanical fan drives. Vibrations generated by the crankshaft and transmitted via the belt can be eliminated by up to 95%. This minimizes noise emissions and losses in the mechanical drive.

Benefits at a glance

- Power transfer optimization

- Significant noise reduction in the mechanical drive

- Practically vibration-free belt running

- High flexibility

- Reducing drivetrain wear for maximum durability and efficiency

Technical specifications

Tensioner pulleys with integrated decoupling system

Permissible ambient temperature:

– 30 °C to +110°C (optionally down to -50°C)

Max. input speed:

3000 rpm

Max. torque:

200 Nm

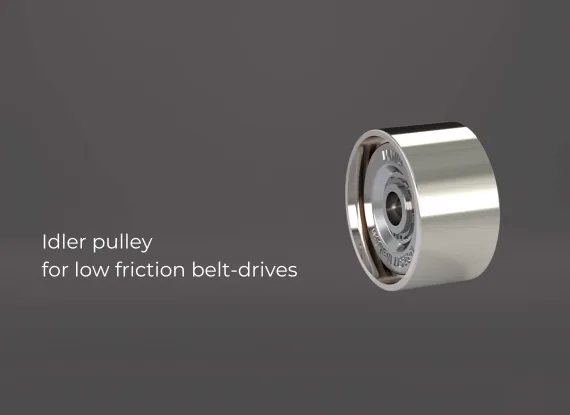

Idler pulleys

Optimization for your engine-compartment

The function of LINNIG’s idler pulleys is to carry the belt in the belt drive and enable a flexible drive layout with sufficient wrap angles for the individual driven units.

LINNIG’s idler pulley plays an important role in engine-compartment optimization. The set themselves apart with their high flexibility: depending on the design and arrangement of the drive train, Solero Technologies – together with the customer – will develop an optimized belt-management system that lives up to individual customer requirements. Our double-row idler pulleys (Idler) fulfil this demand with a robust, lifetime lubricated and sealed construction. Our idler pulleys are used in buses and off-highway applications because they meet the strict requirements.

Benefits at a glance

- Quiet & Efficient

Low-noise, low-friction belt drive - Durable & Maintenance-Free

Lubricated and sealed for life - Flexible Design

Adaptable to various applications - Heat Resistant

Suitable for high-temperature environments - Reliable Performance

Replaceable, double-row ball bearings for extended lifespan

Technical specifications

Idler pulleys

Permissible ambient temperatur:

– 30 °C to +110°C (optionally down to -50°C)

Permissible radial forces:

2,500 N

Max. permissible radial forces (short-term) during starting/stopping:

2,900 N

Max. permissible speed (short-term):

6,000 – 7,000 rpm